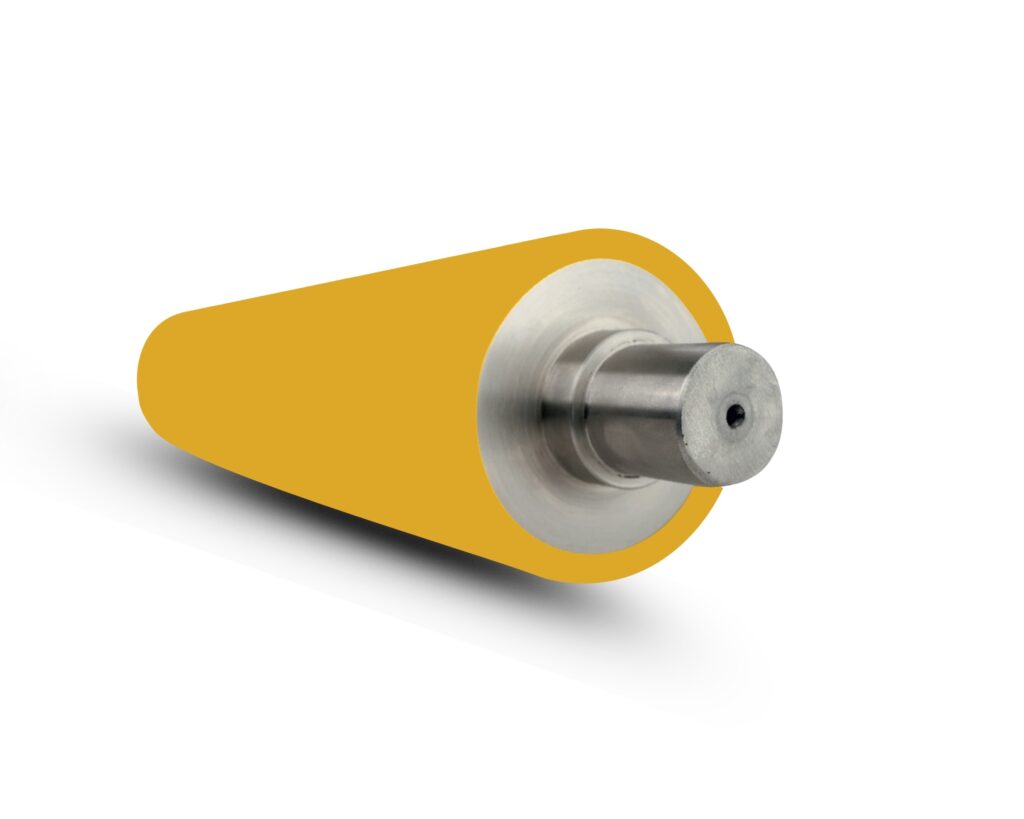

High-quality effect is achieved by the most diverse materials processed with Zenith rollers

TEXTILE INDUSTRY

ZENITH specializes in producing rollers for the textile industry, considering various operational conditions. We manufacture Rollers of different sizes based on the position and application of the Rollers. These rollers are crafted, coated, and maintained using advanced roll technology. Several elements like application, chemical properties, speed, temperature, pressure, roller geometry, deflection, balance, and friction coefficient play a crucial role in determining the quality of these rolls.

1. New Core Design & Fabrication

2. Rubber Covering

3. Re-Grinds (CNC – GRINDER)

4. Core Repair

5. Dynamic Balancing

6. Ultra sonic test

7. Crowning

8. Grooving

9. Engineering Services

10. Extensive Field Support

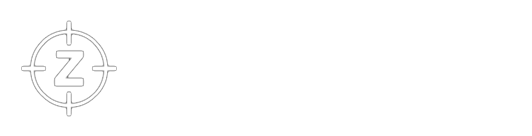

Zentex - DM

Properties & Application For Mercerising & CBR

1. Excellent chemical stability and resistance to alkaline and acidic solutions

2. Our benchmark quality for all treatments including bleaching, dyeing, starching and washing for foulards and intermediate squeezing.

3. Ideal physical charact eristics and resistance to abrasion

4. Great efficiency in squeezing

Hardness: 40-45 Shore A

Temperature: Maximum temperature range: wet 95°C – dry 110°C

Zentex - BR

Properties & Application

For Mercerising. CBR & Stenter, Knitted fabrics

1. Excellent chemical stability and resistance to heated

alkaline solutions.

2. Our finest calibre for foulards, intermediate and final squeezing, designed especially for mercerizing lines.

3. Superior physical characteristics and resistance to

abrasion.

Hardness: 85-90 Shore A

Temperature: Maximum temperature of up to 100°C in

enclosed, damp environments.

Zentex - OX

Properties & Application

For abrasion & squeezing, Mercerising & CBR, Drying &

Stenter Finishing Range

1. Excellent covering for the final squeeze rolls to achieve maximum press-out efficiency.

2. Excellent physical qualities and press-out efficiency of polyurethane compound.

3. Long-lasting end squeeze foulards with high performance and pressure.

4. Final squeeze roll around the perimeter for maximum

press-out efficiency.

5. Superior general chemical and physical qualities.

Hardness: 85-95 Shore A

Temperature: Maximum temperature range: 60 °C for wet

and 90 °C for dry.

Maximum temperature range: wet 95°C – dry 130°C.

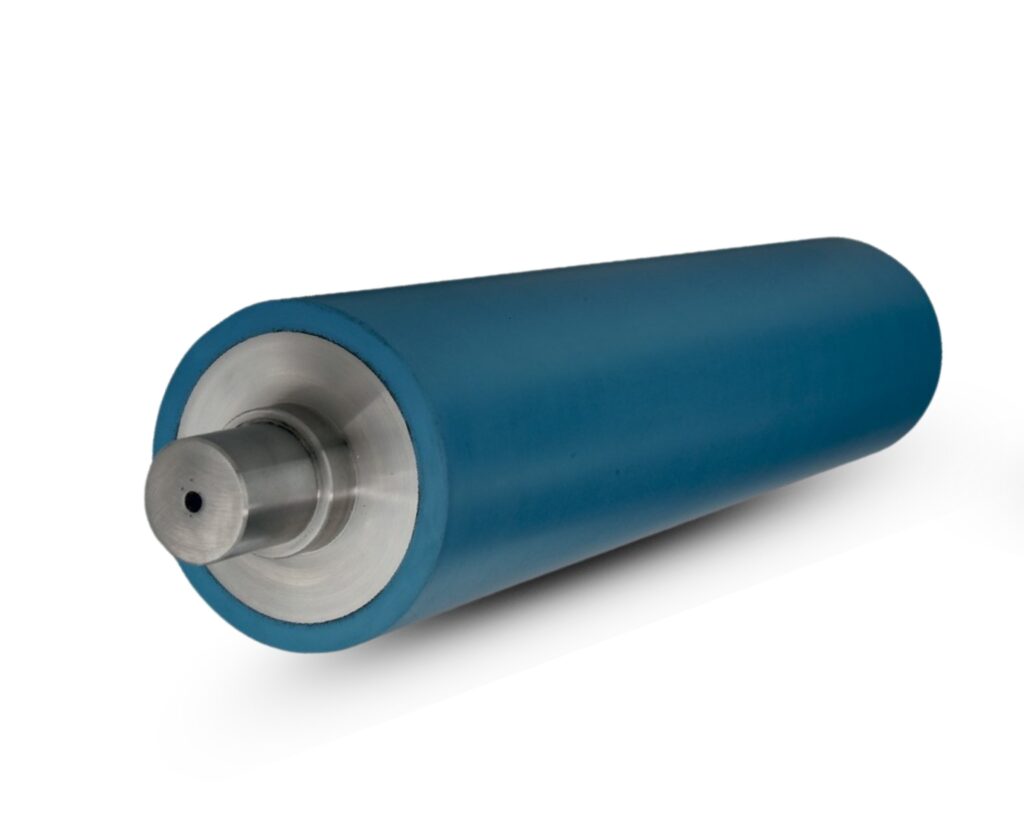

Zentex-WGB

Properties & Application For Sizing

1. Complete stability of the chemical (no swell)

2. A substance designed for use in starching and sizing

3. High consistency of hardness.

Hardness: 70-75-80 Shore A

Temperature: Resistance to temperatures up to 110°C

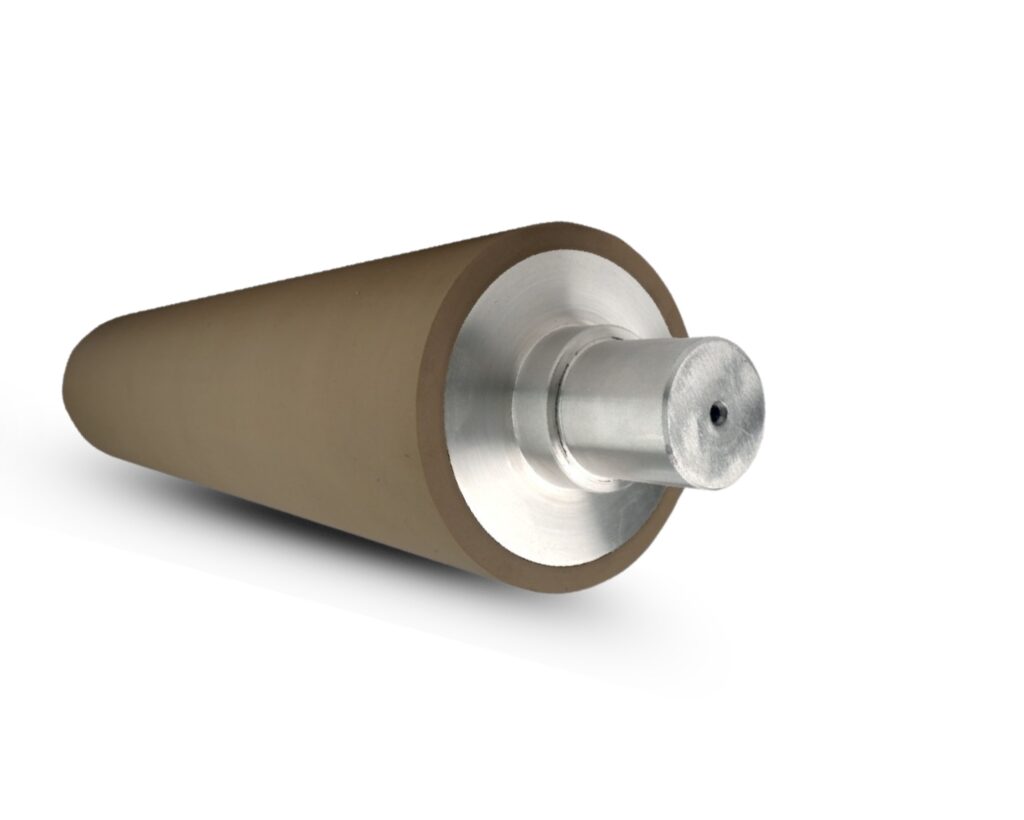

Zentex - HY

Properties & Application

For Stenter Finshing Range & CBR, Knitted fabrics

1. Strong resistance to acidic and alkaline solutions, with excellent chemical stability.

2. Our superior quality for all treatments, including bleaching, dyeing, starching, and washing, for foulards and intermediate squeezing.

3. Superior physical characteristics and resistance to abrasion.

4. High efficiency of squeezing.

Hardness: 60-65 Shore A

Temperature: The maximum temperature for industrial applications is 130°C, and for wet environments, it is 95°C.

Zentex - PU

Properties & Application

Draw Roller for sizing and knitted fabrics, high squeezing and abrasion, for abrasion & squeezing

1. Polyurethane compound including chemical stability and excellent grip

2. Higher mechanical resistance

Hardness: 65-85 Shore A

Zentex - GB

Properties & Application

For Sizing

1. Combines precisely controlled size application to the yarn with flawless squeezing, made possible by a structured (CR), micro porous surface.

2. Compound designed for sizing bath of a sizing yarn line using second squeeze rollers.

Hardness: 70-75-80 Shore A

Temperature: Elevated chemical stability to 110 °C

Zentex - EB

Properties & Application

For Print Washer For Mercerising, CBR, Stenter Finishing Range, Abrasion & Squeezing, for Print Washer

1. Dependable, resilient material

2. Stiff counterpart for section squeezing.

Temperature: Excellent chemical stability to 95 °C