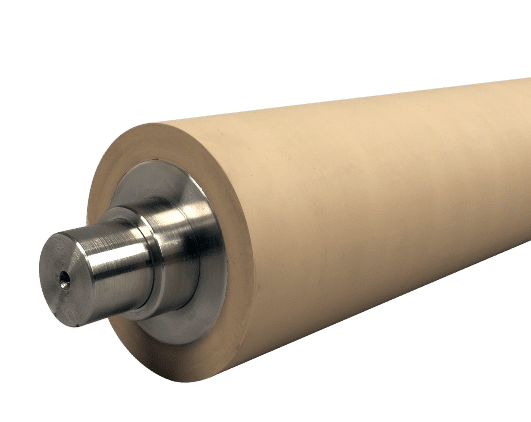

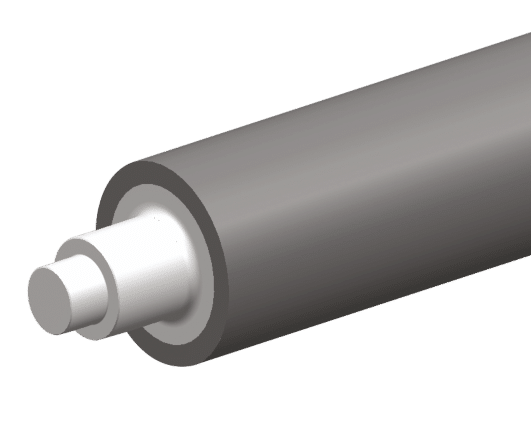

Woven Sacks Rubber Rollers

PP woven bags are bags made of PP plastic in the woven method. Woven, or weaving is a method by many threads or tapes woven in two directions (warp and weft), to form a fabric for plastic industry needs. Polypropylene (PP), is one kind of thermoplastic resin material produced by the polymerization of polypropylene. Its commonly used for Agricultural products, Food Packaging, Cement industries, tours and transport.

Zenith has formulated a special compound for woven sacks industries as there different processes. This specially formulated rubber compound for the Woven sacks industries, provides an excellent resistance to Heat / solvent/Pressure with the best of its physical properties. It stands as the most ideal rubber for Woven sacks industries and its applications.