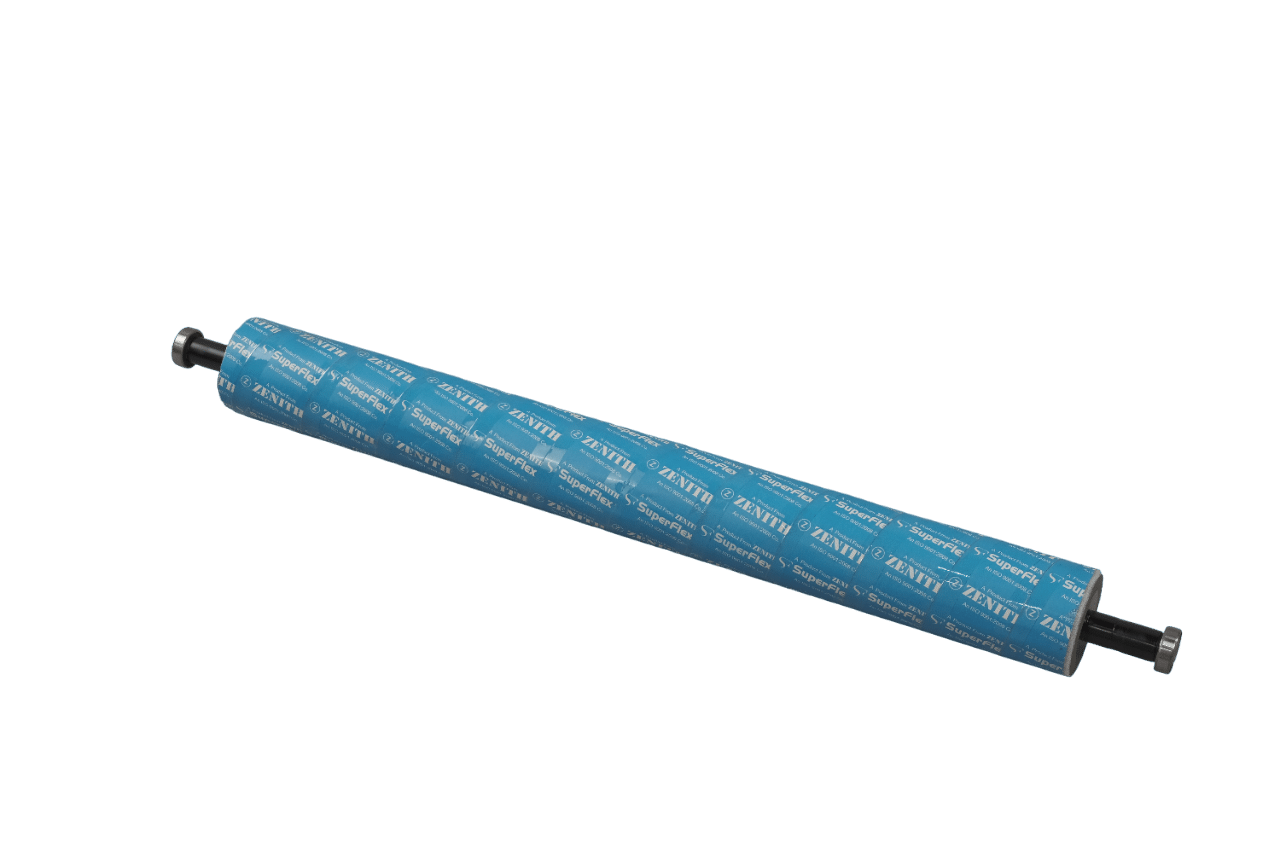

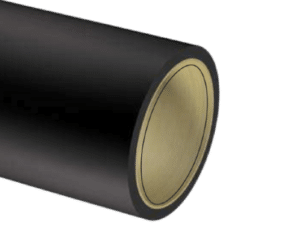

Offering the full range of products and services for rollers right from raw material to finished products.

We provide total solutions for rubber roller refurbishing facilities under one roof, be it machinery, tools, features, QC equipment, raw materials comprising ready-to-use rubber compounds and cores, finished goods, and technical support.

With total turnover experiencing phenomenal growth over the last five years Zenith has emerged as a multi-million dollar conglomerate and a world leader in the rubber roller industry.

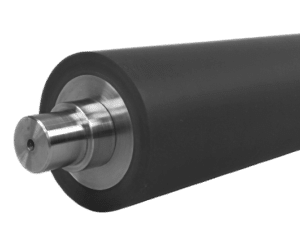

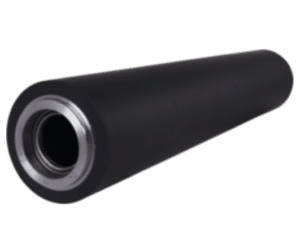

ZENITH LAUNCHES ITS NEW COMPOUND – “SUPER COMBI” for UV Ink/Conventional Ink

Zenith R&D team has developed a new genre of rubber compound for printing rollers, the “Super Combi which has the same chemistry as that of original printing rollers manufactures. The rollers manufactured with this compound maintain dimensional and hardness stability for a longer span of lime.