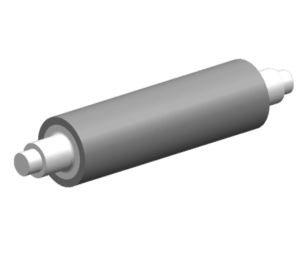

Rollers For Textile Industry

High-quality effect is achieved by the most diverse materials processed with Zenith rollers

Textile Industry

Based on roller operating conditions, ZENITH manufactures rollers for the textile industry. Large metal rolls (up to 10 metres long, 2 metres in diameter, and 50 tons weight) are manufactured, covered, and serviced using roll technology. Application, chemistry, speed, temperature, pressure, Roll geometry, deflection, balance, and coefficient of friction are all factors that influence roll quality.

High-quality effect is achieved by the most diverse materials processed with Zenith rollers. For special finishing, the properties of the coated surfaces are carefully matched to the individual application.

There are countless textiles available, and each individual one has its own properties in terms of material, structure, and elasticity. This is why a roller coating that is perfectly matched to the application is so crucial in the refining of textiles.

Our Products

Impecta Roll

Coating thickness (mm): 15-20mm

Temperature °C up to 120°

Hardness Shore° A 50-85

Applications Used in Acidic Process

Properties

Good Abrasion resistance

Superior performance in Chemical &

Acidic Process

Heavy Padding Roller

Coating thickness (mm): 16-20mm

Temperature °C up to 110

Hardness Shore ° A 85-90

Applications

Used in Bleaching Machines, Mercerize Machine, Dyeing Machine,

Textile wet processing machine.

Properties

Uniform Hardness.

Good Wear and chemical resistance.

Hollow Rubber Roller

Coating thickness (mm): 16-20mm

Temperature °C up to 80-90

Hardness Shore ° A 80-85

Applications

For specialised Mercerizing process

Properties

Imported compound used for better life

High temperature & chemical resists

Small Nip Roller

Coating thickness (mm): 15-20mm

Hardness Shore° A 80-85

Applications

Used in Sizing & Indigo Dyeing Machine

Properties

Superior for light pressure

Good for regular & continuous process

Mangel Roller

Coating thickness (mm): 16-20mm

Temperature °C up to 70-90

Hardness Shore ° A 70-85

Applications

Used in Mercerize Machine

Properties

Good chemical & Temperature resistance

Good durability and wear resistance

Anti Deflection Roller

Coating thickness (mm): 15-20mm

Temperature °C up to 80-90

Hardness Shore °A 70-85

Applications

Sizing & Indigo Dyeing Machine

Properties

Steady chemical picking across the width on yarn

Supreme performance & long life

Drum Roller

Coating thickness (mm): 10-20mm

Temperature °C up to 75

Hardness Shore° A 70-75

Applications

Mercerizing process

Properties

Good for Caustic Process

Superior life and wear resist.

Heavy Nip Roller

Coating thickness (mm): 15-20mm

Temperature °C up to 90-100

Hardness Shore °A 85-95

Applications

Mercerizing process, Textile wet process machine such as CBR, CDR

Properties

Good Abrasion resistance

High temperature and chemical resists

Among our offerings are:

- New Core Design & Fabrication

- Rubber Covering

- Re-Grinds (CNC – GRINDER)

- Core Repair

- Dynamic Balancing

- Ultrasonic test

- Crowning

- Grooving

- Engineering Services

- Extensive Field Support