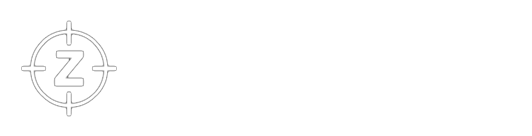

ROLLERS FOR PAPER INDUSTRY

Premium range of covering compound

Paper Industry

Offering Polyurethane & Composite Covering World Class Technology In INDIA AT ZENITH

Polyurethane Covering

Prepared with Special elastomers which have abrasion resistance properties. Designed for high speed and high demanding paper machines. PU Covering has lot more advantages than rubber and has proved its superiority by providing longer life, longer grinding intervals, better resistance to hydrophobisity,

Zenith Rollers offers Pu Covering Suction Press Roll, BDR Roll, Size Press Bottom Roll, and Nipco Press Roll - delivering precision and performance for the paper industry

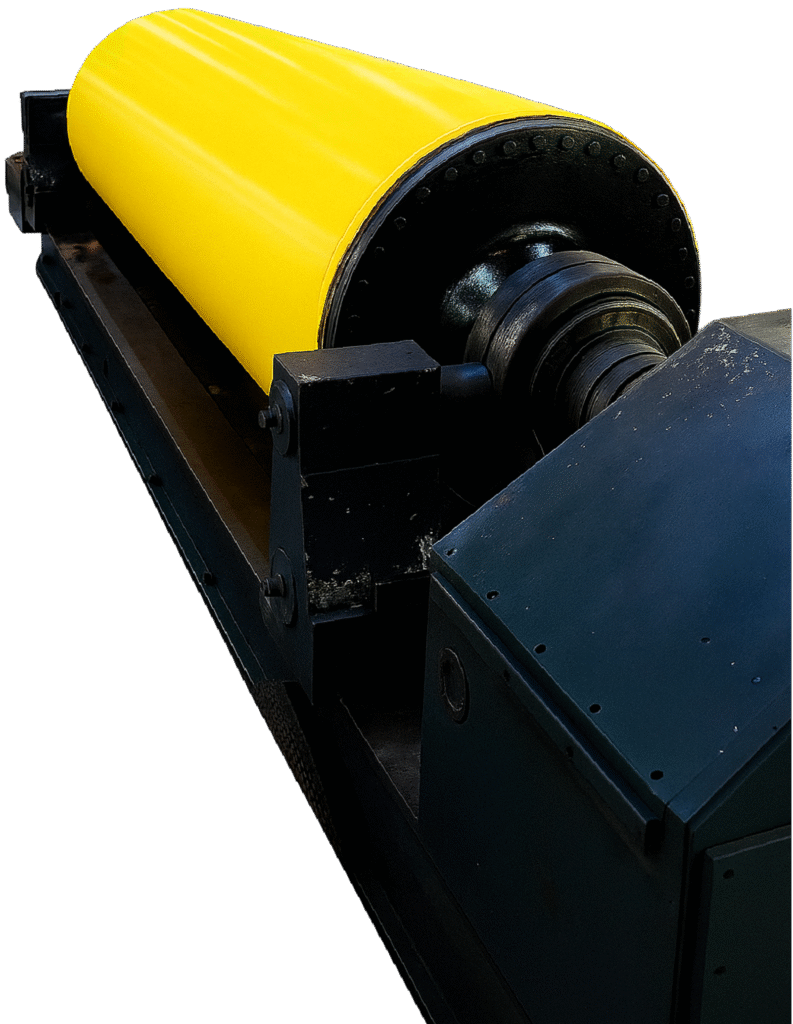

POLYURETHANE COVERING FOR SUCTION PRESS

OFFERS THE BROADEST SELECTION OF ROLL COVERING MATERIALS AVAILABLE BASED ON APPLICATIONS

- CNC DRILLING MACHINE – SUPPORTED BY GERMAN TECHNOLOGY

- COVERING – AUSTRIAN TECHNOLOGY

The Suction Press (SP) Concept provides a considerable improvement in suction roll cover performance. SP is a computerised method developed by Zenith engineers that determines a precise hole pattern for a mix of blind and through drilled holes in the press nip to provide more symmetrical sheet dewatering. The assertions that most suction roll applications can benefit from talking to SP are backed up by field findings.

ZENthane.DP is designed to withstand the hard working conditions at medium and high speeds. It is especially recommended for Suction Press Rolls to manufacture high quality papers.

Advantages of Covering

- Excellent Hydrolysis ability.

- Resistance to heat.

- Increased dimensional stability and resistance to abrasion.

- Allows to work without internal cooling system.

- Allows open area after 50% depending upon the configuration and combination of surface design.

BLIND DRILL ROLLER

ZENthane.P is a polyurethane cover made from the most modern polymers, specially designed for the demanding conditions in paper machines. It was developed for press rolls and allows all combinations of surface designs, up to an open area of over 50%. It is especially recommended for Hard Press and Suction Press (Blind drilled/Suction drilled/Grooved) for paper making machines.

ZENthane.P offers lowest dynamic heat generation. Therefore, it’s best suited for applications with high speed & linear load and/or no internal cooling. The applications design, as well as the applicable linear load is evaluated individually for each position.

Features & Advantage of Covering

- Extremely low heat generation

- Extremely good wear resistance

- Resistance against high dynamic load

- Special hydrolytic stability

- Special high elastic cover

- Advantages

- Higher Open area possible

- Applicable for highly dynamic loaded position

- Lower energy consumption

SIZE PRESS | FILM PRESS ROLLS

ZENthane.S is a polyurethane cover made from most modern polymers, specially designed for the demanding conditions in paper machines. It is the new polyurethane cover generation resistance to hydrolysis that allows us to apply more uniform layer of coating at medium and high speed machines.

ZENthane.S was developed for size press and film press rolls. The application and design, as well as the applicable linear load is evaluated individually for each position.

Features & Advantage of Covering

- Extremely low heat generation

- Extremely good wear resistance

- Resistance against high dynamic load

- Special hydrolytic stability

- Special high elastic cover

Advantages

- Applicable for highly dynamic loaded position

- Lower energy consumption

COMPOSITE COVERING

The Covering is manufactured from state of the art

materials such as an optimized combination of thermoset epoxy resin with special fillers and fibers for best performance. Its benefits include:

- Longer working life

- Higher resistance to temperature (up to +100° and even more)

Zenith Launches Nanotek & Nanorok Compoisite Compound. Composite calender covers are made of modern fiber reinforced compound. Special fillers ensure the optimal hardness, robustness and surface smoothness.

Advantages are depending on the existing situation and previously used roll covers:

- Improvement of paper quality

- Avoiding of paper blackening and paper mottling

- Higher bulk of paper

- Lifetime of cover

- Marking resistance

- Allowing higher speed and load on machine

- Less downtime of machine

- Allows continues doctoring

DELIVERING DYNAMIC SOLUTIONS

Modern paper machines are built to manufacture/produce more at a faster rate. We have rubber-covering options that allow for optimum load usage without risk of crushing, as well as maximum covering resiliency, even at increasing hardness, in order to maintain a consistent Nip Zone.

ROLLS COVERING

Zenith has created a Premium range of compound Excel, Ultimex, Super Rock, and Ultra Super Rock with superior release characteristics, dimensional stability, chemical resistance, steam environment, thermal stability, and high pressure operation. The material can sustain a Nip Load of up to 500 kg per linear centimetre. The graph below shows the newly developed superior compound.

HYBRID COVERS FOR PRESS SECTION

SUPERFLEX BD

“Superflex BD is a special hybrid compound developed with Italian technology. It is made out of specialized rubber & polymers to achieve better and wider NIP, dewatering, high linear load and much better resilience as compared to normal rubber covers. ” Superflex BD cover has been developed for High Speed and Long Run machine.

SERVICES WE OFFER ✓

1. New Core Design & Fabrication

2. Rubber Covering

3. Re-Grinds

4. Core Repair

5. Ultra sonic test & Balancing machine

6. Crowning

7. Grooving

8. Engineering Services

9. Extensive Field Support

CAPACITY

We have manufactured roller upto

following sizes:

Lengthn-8000mm

Diameter-2000mm

Weight-upto 30 tonne

We manufacture more than 100 new rollers per month. And the Roller size accuracy upto 5 microns is maintained. Shore hardness of Rubber & run out standards are properly adhered to for each & every roller.