FLEXO PRINTING RUBBER ROLLERS

Flexography is the major process used to print on packaging materials. Flexography printing basically prints on LD/HM/PP/Nylon/HDPP/HDPE/Poly/Non-woven/corrugated boxes/disposable cups/tapes and wrappers.

The selection of rubber compounds is the key of printing performance in Flexography. All rubber compounds coverings possess unique properties that determine suitable for particular applications.

Flexography uses fast drying inks for printing process and can print on absorbent and non-absorbent substrates that is the reason it is important that the rubber rollers used in these machines are suitable for these kind of printing process. Some of the characteristics of the Flexography rubber rollers have been highlighted below.

Excellent Chemical resistance:- As this industries uses various types of inks which contains different types of solvents and chemicals which is used to maintain ink viscosity or flow at the time of printing. Zenith rubber compound has been formulated to withstand such usages.

Hardness stability:- As in all types of rubber roller uses in flexible packaging the Hardness of rubber rollers is the most important factor. Swelling or softening of the compound is restricted and hence maintains the hardness of the roller stability.

Abrasion Resistance:- Zenith has formulated the rubber compound which do not wear out easily despite of use of various solvent and chemical in the inks, there by maintaining its structure.

Longer life of the rubber roller:- As all industries working for cost saving to increase profit of the company. In this view Zenith formulated the rubber compound which has longrun-ability.

Zenith provides all types of rubber rollers for Stack flexo and Drum flexo printing machine in flexography industries.

1). INK TRANSFER ROLLER

Product Features

Dynamically Balanced

Excellent ink transfer property.

Smooth surface

Free from swelling and crack.

Excellent chemical, solvent and Heat resistant property.

Anti-static properties.

Suitable for all types of printing speeds.

Excellent bonding with shell.

Product Specification

Hardness-45 to 75 Shore A

Pressure-0.5 to 6 kg

Tolerance – OD+/-0.03 to +/-0.05

-Length+/-0.03 to +/-0.05

2). PRINTING IMPRESSION (NIP) ROLLER

Product Features

Dynamically Balanced

Smooth surface

Free from swelling and crack.

Anti-static properties.

Suitable for all types of printing speeds.

Excellent bonding with shell.

Product Specification

Hardness-60-80 Shore A

Pressure-0.5 to 6 kg

Temperature: Max-60 deg

Tolerance OD+/-0.03 to +/-0.05

-Length+/-0.03 to +/-0.05

3). OUT FEED ROLLER

Product Features

Dynamically Balanced

Smooth surface

Anti-static properties.

Excellent bonding with shell.

Product Specification

Hardness-60-75 Shore A

Pressure-0.5 to 6 kg

Temperature: Max-60 deg

Tolerance-OD-+/-0.03 to +/-0.05

-Length+/-0.03 to +/-0.05

4). CUTTING (GROOVE AND SILICON) ROLLERS

Product Features

Dynamically Balanced

Anti-static properties

Excellent bonding with shell.

Accurate Groove profile

Product Specification

Hardness-60-70 Shore A

Pressure-0.5 to 6 kg

Temperature: Max-60 deg and Max-150 (Silicon

Tolerance OD/-0.03 to +/-0.05

-Length+/-0.03 to +/-0.05

5). INK FURNISHING ROLLERS

Product Features

Dynamically Balanced

Excellent solvent resistant like Ethyl, toluene (Max-25%) MEK, MIBK and Heat resistant

property.

Excellent Anti-static properties.

Excellent bonding with shell.

Smooth surface and have good ink transfer property to smallest cylinder cell.

Product Specification

Hardness-60-75 Shore A

Temp Resistance – Max 80.deg.c.

Tolerance – OD+/-0.03 to +/-0.05

-Length+/-0.03 to +/-0.05

6). SLITTING LAY-ON AND NIP RUBBER ROLLERS

Product Features

Smooth surface and have good strength and stability.

Dynamically Balanced

Excellent performance on all types of substrate.

Excellent Heat resistant property.

Excellent Anti-static properties.

Suitable for all types of Slitting speeds.

Excellent bonding with shell.

Product Specification

Hardness-65-75 Shore A

Pressure resistance-0.5 to 6 kg

Temp Resistance-Max 80.deg.c.

Tolerance-OD-+/-0.03 to +/-0.05

-Length +/-0.03 to +/-0.05

7). POUCHING AND GROOVE RUBBER ROLLERS

Product Features

Suitable for all types of pouching process.

Dynamically Balanced

Excellent Heat resistant property.

Excellent Anti-static properties.

Excellent bonding with shell.

Product Specification

Smooth surface and have good strength and stabilit

Hardness 60-70 Shore A

Pressure resistance-0.5 to 6kg

Temp Resistance Max 80.deg.c. Tolerance-OD-+/-0.03 to +/-0.05

-Length +/-0.03 to +/-0.05

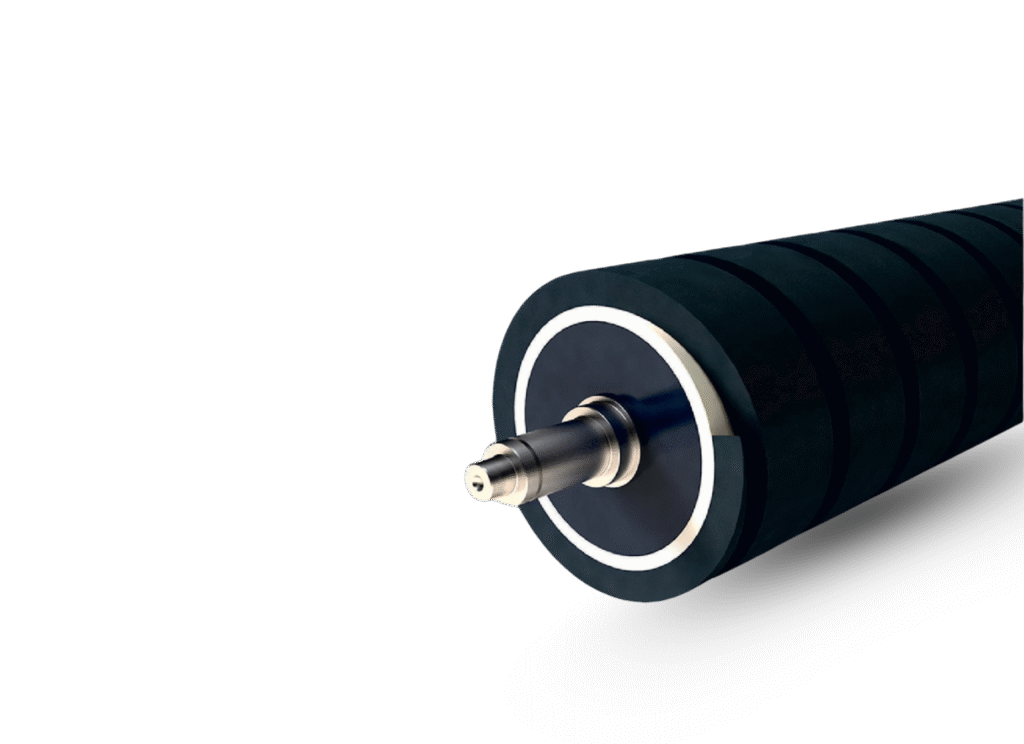

ZENITH LAUNCHES ANILOX ROLLERS FOR FLEXOGRAPHY PRINTING

Flexography Printing

Flexography is a form of printing process which utilizers a flexible relief plate. It is essentially a modern version of letterpress which can be used for printing on almost any type of substrate, including plastic, metalic films, cellophane, and paper. It is widely used for printing on the non-porous substrates required for various types of food packaging.

Anilox Rollers

Anilox Rollers are essential componets in Flexo Printing and Coating. Anilox Rollers are precised engraved rollers, designed and manufactured to apply exact volume of ink/coating, cooperating with doctor blade chamber, to printing plates. Compared with traditional Machine Engraved Chrome Coated Anilox Rollers. Anilox Rollers are measured by screen counting, angle of engraving, depth and volume. An optimum engraving is achieved when all these factors balanced in relation to specific requirement of printing and coating.

Chrome Centre Anilox from ZENITH, provides high quality chrome plate which has good chemical stability and its hard surface provides excellent anticorrosion and wear resistance. Round, smooth and uniform cell ensures efficient and even ink release. Controlelled cell opening and depth ensures precise amount of ink transfer.